Lukashchuk, A. et al. Photonic-electronic integrated circuit-based coherent LiDAR engine. Nat. Commun. 15, 3134 (2024).

Li, X. K. et al. High-efficiency reinforcement learning with hybrid architecture photonic integrated circuit. Nat. Commun. 15, 1044 (2024).

Wang, Y. B. et al. Photonic-circuit-integrated titanium: sapphire laser. Nat. Photonics 17, 338–345 (2023).

El Helou, C. et al. Mechanical integrated circuit materials. Nature 608, 699–703 (2022).

Yang, Y. X. et al. A non-printed integrated-circuit textile for wireless theranostics. Nat. Commun. 12, 4876 (2021).

Liu, Y. et al. A photonic integrated circuit-based erbium-doped amplifier. Science 376, 1309–1313 (2022).

Moore, G. E. Progress in digital integrated electronics. In Proc. 1975 IEEE International Electron Devices Meeting. 11–13 (IEEE, Washington, D.C., USA,1975).

Huang, L. Y. et al. Sub-wavelength patterned pulse laser lithography for efficient fabrication of large-area metasurfaces. Nat. Commun. 13, 5823 (2022).

Liu, T. Q. et al. Ultrahigh-printing-speed photoresists for additive manufacturing. Nat. Nanotechnol. 19, 51–57 (2024).

Tian, X. L. et al. Crosslinking-induced patterning of MOFs by direct photo-and electron-beam lithography. Nat. Commun. 15, 2920 (2024).

Qin, N. et al. 3D electron-beam writing at sub-15 nm resolution using spider silk as a resist. Nat. Commun. 12, 5133 (2021).

Zhu, C. X. et al. Electron beam lithography on nonplanar and irregular surfaces. Microsyst. Nanoeng. 10, 52 (2024).

Liu, X. Q. et al. Biomimetic sapphire windows enabled by inside-out femtosecond laser deep-scribing. PhotoniX 3, 1 (2022).

Garcia, R., Knoll, A. W. & Riedo, E. Advanced scanning probe lithography. Nat. Nanotechnol. 9, 577–587 (2014).

Kim, G. et al. Binary-state scanning probe microscopy for parallel imaging. Nat. Commun. 13, 1438 (2022).

Kudryashov, S. I. et al. Direct femtosecond-laser writing of optical-range nanoscale metagratings/metacouplers on diamond surfaces. Appl. Phys. Lett. 115, 073102 (2019).

Hayasaki, Y. et al. Variable holographic femtosecond laser processing by use of a spatial light modulator. Appl. Phys. Lett. 87, 031101 (2005).

Somers, P. et al. Rapid, continuous projection multi-photon 3D printing enabled by spatiotemporal focusing of femtosecond pulses. Light Sci. Appl. 10, 199 (2021).

He, M. F. et al. Single-color peripheral photoinhibition lithography of nanophotonic structures. PhotoniX 3, 25 (2022).

Lee, Y. et al. Ultra-thin light-weight laser-induced-graphene (LIG) diffractive optics. Light Sci. Appl. 12, 146 (2023).

Balena, A. et al. Recent advances on high-speed and holographic two-photon direct laser writing. Adv. Funct. Mater. 33, 2211773 (2023).

Farsari, M. et al. Two-photon fabrication. Nat. Photonics 3, 450–452 (2009).

Saha, S. K. et al. Scalable submicrometer additive manufacturing. Science 366, 105–109 (2019).

Geng, Q. et al. Ultrafast multi-focus 3-D nano-fabrication based on two-photon polymerization. Nat. Commun. 10, 2179 (2019).

Ouyang, W. Q. et al. Ultrafast 3D nanofabrication via digital holography. Nat. Commun. 14, 1716 (2023).

Cao, C. et al. Ultra-high precision nano additive manufacturing of metal oxide semiconductors via multi-photon lithography. Nat. Commun. 15, 9216 (2024).

Guan, L. L. et al. Light and matter co-confined multi-photon lithography. Nat. Commun. 15, 2387 (2024).

Wang, L. et al. Plasmonic nano-printing: large-area nanoscale energy deposition for efficient surface texturing. Light Sci. Appl. 6, e17112 (2017).

Zou, T. T. et al. High-speed femtosecond laser plasmonic lithography and reduction of graphene oxide for anisotropic photoresponse. Light Sci. Appl. 9, 69 (2020).

Choi, H. et al. Realization of high aspect ratio metalenses by facile nanoimprint lithography using water-soluble stamps. PhotoniX 4, 18 (2023).

Kim, J. et al. One-step printable platform for high-efficiency metasurfaces down to the deep-ultraviolet region. Light Sci. Appl. 12, 68 (2023).

Zhang, B. et al. Ultrafast laser-induced self-organized nanostructuring in transparent dielectrics: fundamentals and applications. PhotoniX 4, 24 (2023).

Blaicher, M. et al. Hybrid multi-chip assembly of optical communication engines by in situ 3D nano-lithography. Light Sci. Appl. 9, 71 (2020).

Zhang, B. et al. Self-organized phase-transition lithography for all-inorganic photonic textures. Light Sci. Appl. 10, 93 (2021).

Li, Z. Q. et al. Realising high aspect ratio 10 nm feature size in laser materials processing in air at 800 nm wavelength in the far-field by creating a high purity longitudinal light field at focus. Light Sci. Appl. 11, 339 (2022).

Liu, Y. N. et al. Ultrafast laser one-step construction of 3D micro-/nanostructures achieving high-performance zinc metal anodes. PhotoniX 5, 6 (2024).

Li, J. Q. et al. Nanoscale multi-beam lithography of photonic crystals with ultrafast laser. Light Sci. Appl. 12, 164 (2023).

Gan, Z. F. et al. Spatial modulation of nanopattern dimensions by combining interference lithography and grayscale-patterned secondary exposure. Light Sci. Appl. 11, 89 (2022).

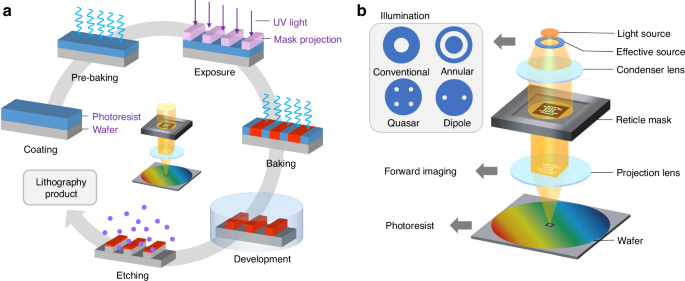

Wu, Q. Photolithography Process Near the Diffraction Limit (Tsinghua University Press, 2020).

Rayleigh, J. W. S. Investigations in optics, with special reference to the spectroscope. Lond. Edinb. Dublin Philos. Mag. J. Sci. 8, 261–274 (1879).

Levinson, H. J. Principles of Lithography. 2nd edn. (SPIE Press, 2005).

Markle, D. A. A new projection printer. Solid State Technol. 17, 50–53 (1974).

Wei, Y. Y. et al. Computational Lithography and Layout Optimization (Electronics Industry Press, 2021).

Liu, P. Mask synthesis using machine learning software and hardware platforms. Proc SPIE 11327, Optical Microlithography XXXIII (SPIE, San Jose, CA, USA, 2020).

Cecil, T. et al. Establishing fast, practical, full-chip ILT flows using machine learning. Proc SPIE 11327, Optical Microlithography XXXIII (SPIE, San Jose, CA, USA, 2020).

Shi, X. L. et al. Physics based feature vector design: a critical step towards machine learning based inverse lithography. Proc SPIE 11327, Optical Microlithography XXXIII (SPIE, San Jose, CA, USA, 2020).

Adam, K. et al. Using machine learning in the physical modeling of lithographic processes. Proc SPIE 10962, Design-Process-Technology Co-optimization for Manufacturability XIII (SPIE, San Jose, CA, USA, 2019).

Kim, Y. S. et al. OPC model accuracy study using high volume contour based gauges and deep learning on memory device. Proc SPIE 10959, Metrology, Inspection, and Process Control for Microlithography XXXIII (SPIE, San Jose, CA, USA, 2019).

Ma, X. et al. Fast lithography aerial image calculation method based on machine learning. Appl. Opt. 56, 6485–6495 (2017).

Lin, J. X. et al. Fast extreme ultraviolet lithography mask near-field calculation method based on machine learning. Appl. Opt. 59, 2829–2838 (2020).

Liu, P. et al. Fast 3D thick mask model for full-chip EUVL simulations. Proc SPIE 8679, Extreme Ultraviolet (EUV) Lithography IV (SPIE, San Jose, CA, USA, 2013).

Zhang, H. et al. 3D rigorous simulation of defective masks used for EUV lithography via machine learning-based calibration. Acta Opt. Sin. 38, 1222002 (2018).

Tanabe, H., Sato, S. & Takahashi, A. Fast 3D lithography simulation by convolutional neural network. Proc. SPIE 11518, Design-Process-Technology Co-optimization XV (SPIE, 2021).

Lin, J. X. et al. Fast mask near-field calculation using fully convolution network. Proc. 2020 International Workshop on Advanced Patterning Solutions (IWAPS) 1–4 (IEEE, Chengdu, China, 2020).

Kareem, P. & Shin, Y. Synthesis of lithography test patterns using machine learning model. IEEE Trans. Semiconduct. Manuf. 34, 49–57 (2021).

Ye, W. et al. LithoGAN: end-to-end lithography modeling with generative adversarial networks. Proc. 2019 56th ACM/IEEE Design Automation Conference 1–6 (IEEE, Las Vegas, NV, USA, 2019).

Ye, W. et al. TEMPO: fast mask topography effect modeling with deep learning. Proc. 2020 International Symposium on Physical Design 127–134 (ACM, Taipei, China, 2020).

Lan, S. et al. Deep learning assisted fast mask optimization. Proc. SPIE 10587, Optical Microlithography XXXI. (SPIE, San Jose, CA, USA, 2018).

Lin, J. X. et al. Learning-based compressive sensing method for EUV lithographic source optimization. Opt. Express 27, 22563–22581 (2019).

Lin, J. X. et al. Fast aerial image model for EUV lithography using the adjoint fully convolutional network. Opt. Express 30, 11944–11958 (2022).

Li, Z. Q. et al. High-precision lithography thick-mask model based on a decomposition machine learning method. Opt. Express 30, 17680–17697 (2022).

Li, Z. Q. et al. Decomposition-learning-based thick-mask model for partially coherent lithography system. Opt. Express 31, 20321–20337 (2023).

Li, Z. Q. et al. Fast diffraction model of an EUV mask based on asymmetric patch data fitting. Appl. Opt. 62, 6561–6570 (2023).

Li, Z. Q. et al. Fast source mask co-optimization method for high-NA EUV lithography. Opto-Electron. Adv. 7, 230235 (2024).

Xia, J. H. et al. Modeling of silicon carbide ECR etching by feed-forward neural network and its physical interpretations. IEEE Trans. Plasma Sci. 38, 1091–1096 (2010).

Kim, B. & Lee, B. T. Prediction of silicon oxynitride plasma etching using a generalized regression neural network. J. Appl. Phys. 98, 034912 (2005).

Shiraishi, M. et al. Flare modeling and calculation on EUV optics. Proc. SPIE 7636, Extreme Ultraviolet (EUV) Lithography IV (pp. 763629, SPIE, San Jose, CA, USA, 2010).

Shim, S., Choi, S. & Shin, Y. Machine learning (ML)-based lithography optimizations. Proc. 2016 IEEE Asia Pacific Conference on Circuits and Systems (APCCAS) 530–533 (IEEE, Jeju, Korea (South), 2016).

Shim, S. & Shin, Y. Etch proximity correction through machine-learning-driven etch bias model. Proc. SPIE 9782, Advanced Etch Technology for Nanopatterning V (SPIE, San Jose, CA, USA, 2016).

Chen, R. et al. ETCH model based on machine learning. Proc. 2020 China Semiconductor Technology International Conference (CSTIC) 1–4 (IEEE, Shanghai, China, 2020).

Pan, Y. H. et al. Efficient informatics-based source and mask optimization for optical lithography. Appl. Opt. 60, 8307–8315 (2021).

Ma, X. et al. Fast pixel-based optical proximity correction based on nonparametric kernel regression. J. Micro/Nanolithogr. MEMS MOEMS 13, 043007 (2014).

Luo, K. S. et al. SVM based layout retargeting for fast and regularized inverse lithography. J. Zhejiang Univ. Sci. C. 15, 390–400 (2014).

Luo, R. Optical proximity correction using a multilayer perceptron neural network. J. Opt. 15, 075708 (2013).

Yang, H. Y. et al. Imbalance aware lithography hotspot detection: a deep learning approach. J. Micro/Nanolithogr. MEMS MOEMS 16, 033504 (2017).

Yang, H. Y. et al. GAN-OPC: mask optimization with lithography-guided generative adversarial nets. Proc. 55th Annual Design Automation Conference 131 (IEEE, San Francisco, CA, USA, 2018).

Sim, W. et al. Automatic correction of lithography hotspots with a deep generative model. SPIE Adv. Lithogr. 10961, 1096105 (2019).

Zhu, J. Y. et al. Unpaired image-to-image translation using cycle-consistent adversarial networks. Proc. 2017 IEEE International Conference on Computer Vision 2242–2251 (IEEE, Venice, Italy, 2017).

Zhang, Y. J. & Ye, W. J. Deep learning–based inverse method for layout design. Struct. Multidiscip. Optim. 60, 527–536 (2019).

Zhang, S. G. et al. Fast optical proximity correction based on graph convolution network. Proc. SPIE 11613, Optical Microlithography XXXIV (SPIE, 2021).

Ma, X. et al. Model-driven convolution neural network for inverse lithography. Opt. Express 26, 32565–32584 (2018).

Ma, X. & Arce, G. R. Generalized inverse lithography methods for phase-shifting mask design. Opt. Express 15, 15066–15079 (2007).

Zheng, X. Q. et al. Model-informed deep learning for computational lithography with partially coherent illumination. Opt. Express 28, 39475–39491 (2020).

Ma, X., Zheng, X. Q. & Arce, G. R. Fast inverse lithography based on dual-channel model-driven deep learning. Opt. Express 28, 20404–20421 (2020).

Wei, Y. Y. Advanced Lithography Theory and Application of VLSI (Science Press, 2016).

Schellenberg, F. M. A history of resolution enhancement technology. Opt. Rev. 12, 83–89 (2005).

Shibuya, M. Resolution enhancement techniques for optical lithography and optical imaging theory. Opt. Rev. 4, 151–160 (1997).

Shi, W. J. et al. Computational lithography technology under chip manufacture context. Laser Optoelectron. Prog. 59, 0922001 (2022).

Ma, X. & Arce, G. R. Computational Lithography. (John Wiley & Sons, Hoboken, 2011).

Shi, R. et al. The selection and creation of the rules in rules-based optical proximity correction. Proc. ASICON 2001 4th International Conference on ASIC Proceedings 50–53 (IEEE, Shanghai, China, 2001).

Cobb, N. B., Zakhor, A. & Miloslavsky, E. A. Mathematical and CAD framework for proximity correction. Proc. SPIE 2726, Optical Microlithography IX 208–222 (SPIE, Santa Clara, CA, USA, 1996).

Liu, A. C. & Lin, B. J. A study of projected optical images for typical IC mask patterns illuminated by partially coherent light. IEEE Trans. Electron Devices 30, 1251–1263 (1983).

Yong, L., Zakhor, A. & Zuniga, M. A. Computer-aided phase shift mask design with reduced complexity. IEEE Trans. Semicond. Manuf. 9, 170–181 (1996).

Lucas, K. D. et al. Model-based OPC for first-generation 193-nm lithography. Proc. SPIE 4346, Optical Microlithography XIV 119–130 (SPIE, Santa Clara, CA, USA, 2001).

Hsu, S. et al. An innovative source-mask co-optimization (SMO) method for extending low k1 imaging. Proc. SPIE 7140, Lithography Asia 2008 220–229 (SPIE, Taipei, China, 2008).

Tolani, V. et al. Source-mask co-optimization (SMO) using level set methods. Proc. SPIE 7488, Photomask Technology 2009 (SPIE, Monterey, CA, USA, 2009).

Chiu, M. C. et al. Challenges of 29nm half-pitch NAND Flash STI patterning with 193nm dry lithography and self-aligned double patterning. Proc. SPIE 7140, Lithography Asia 2008 (SPIE, Taipei, China, 2008).

Tsai, M. C. et al. Full-chip source and mask optimization. Proc. SPIE 7973, Optical Microlithography XXIV (SPIE, San Jose, CA, USA, 2011).

Saleh, B. E. A. & Sayegh, S. I. Reduction of errors of microphotographic reproductions by optimal corrections of original masks. Opt. Eng. 20, 205781 (1981).

Pang, L. Y. Inverse lithography technology: 30 years from concept to practical, full-chip reality. J. Micro/Nanopattern. Mater. Metrol. 20, 030901 (2021).

Pang, L. et al. TrueMask ILT MWCO: full-chip curvilinear ILT in a day and full mask multi-beam and VSB writing in 12 h for 193i. Proc. SPIE 11327, Optical Microlithography XXXIII (SPIE, San Jose, CA, USA).

Nashold, K. M. & Saleh, B. E. A. Image construction through diffraction-limited high-contrast imaging systems: an iterative approach. J. Opt. Soc. Am. A 2, 635–643 (1985).

Liu, Y. & Zakho, A. Binary and phase-shifting image design for optical lithography. Proc. SPIE 1463, Optical/Laser Microlithography IV (pp. 382–399. SPIE, San Jose, CA, USA, 1991).

Rosenbluth, A. et al. Optimum mask and source patterns to print a given shape. J. Micro/Nanolithogr. MEMS MOEMS 1, 13–30 (2002).

Wang, Y. T. et al. Automated design of halftoned double-exposure phase-shifting masks. Proc. SPIE 2440, Optical/Laser Microlithography VIII 290–301 (SPIE, Santa Clara, CA, USA, 1995).

Jang, S. H. et al. Manufacturability evaluation of model-based OPC masks. Proc. SPIE 4889, 22nd Annual BACUS Symposium on Photomask Technology 520–529 (SPIE, Monterey, CA, USA, 2002).

Fuhner, T. & Erdmann, A. Improved mask and source representations for automatic optimization of lithographic process conditions using a genetic algorithm. Proc. SPIE 5754, Optical Microlithography XVIII 415–426 (SPIE, San Jose, CA, USA, 2005).

Lin, B. J. Immersion lithography and its impact on semiconductor manufacturing. Proc. SPIE 5377, Optical Microlithography XVII 46–67 (SPIE, Santa Clara, CA, USA, 2004).

Osher, S. & Sethian, J. A. Fronts propagating with curvature-dependent speed: algorithms based on Hamilton-Jacobi formulations. J. Comput. Phys. 79, 12–49 (1988).

Abrams, D. & Pang, L. Y. Fast inverse lithography technology. Proc. SPIE 6154, Optical Microlithography XIX (SPIE, San Jose, CA, USA, 2006).

Hung, C. Y. et al. Pushing the lithography limit: applying inverse lithography technology (ILT) at the 65nm generation. Proc. SPIE 6154, Optical Microlithography XIX (SPIE, San Jose, CA, USA, 2006).

Lin, B. et al. Inverse lithography technology at chip scale. Proc. SPIE 6154, Optical Microlithography XIX (pp. 615414. SPIE, San Jose, CA, USA, 2006).

Granik, Y. Fast pixel-based mask optimization for inverse lithography. J. Micro/Nanolithogr., MEMS, MOEMS 5, 043002 (2006).

Borodovsky, Y. et al. Pixelated phase mask as novel lithography RET. Proceedings of SPIE 6924, Optical Microlithography XXI (SPIE, San Jose, CA, USA, 2008).

Singh, V. et al. Making a trillion pixels dance. Proceedings of SPIE 6924, Optical Microlithography XXI (SPIE, San Jose, CA, USA, 2008).

Torunoglu, I. et al. A GPU-based full-chip inverse lithography solution for random patterns. Proceedings of SPIE 7641, Design for Manufacturability through Design-Process Integration IV (SPIE, San Jose, CA, USA, 2010).

Ma, X. & Arce, G. R. Generalized inverse lithography methods for phase-shifting mask design. Proceedings of SPIE 6520, SPIE Advanced Lithography (SPIE, San Jose, CA, USA, 2007).

Ma, X. & Arce, G. Binary mask optimization for inverse lithography with partially coherent illumination. J. Opt. Soc. Am. A 25, 2960–2970 (2008).

Maa, X. & Arce, G. PSM design for inverse lithography with partially coherent illumination. Opt. Express 16, 20126–20141 (2008).

Zhang, J. Y. et al. A highly efficient optimization algorithm for pixel manipulation in inverse lithography technique. Proceedings of 2008 IEEE/ACM International Conference on Computer-Aided Design 480–487 (SPIE, San Jose, CA, 2008).

Shen, S. H., Yu, P. & Pan, D. Z. Enhanced DCT2-based inverse mask synthesis with initial SRAF insertion. Proceedings of SPIE 7122, Photomask Technology 2008 (SPIE, Monterey, CA, USA, 2008).

Yang, Y. W., Shi, Z. & Shen, S. H. Seamless-merging-oriented parallel inverse lithography technology. J. Semiconduct. 30, 106002 (2009).

Lam, E. Y. & Wong, A. K. K. Computation lithography: virtual reality and virtual virtuality. Opt. Express 17, 12259–12268 (2009).

Jia, N. N. & Lam, E. Y. Machine learning for inverse lithography: using stochastic gradient descent for robust photomask synthesis. J. Opt. 12, 045601 (2010).

Lv, W., Xia, Q. & Liu, S. Y. Mask-filtering-based inverse lithography. J. Micro/Nanolithogr. MEMS MOEMS 12, 043003 (2013).

Lv, W. et al. Level-set-based inverse lithography for mask synthesis using the conjugate gradient and an optimal time step. J. Vac. Sci. Technol. B 31, 041605 (2013).

Lv, W. et al. Cascadic multigrid algorithm for robust inverse mask synthesis in optical lithography. J. Micro/Nanolithogr. MEMS MOEMS 13, 023003 (2014).

Shen, Y. et al. Level-set-based inverse lithography for photomask synthesis. Opt. Express 17, 23690–23701 (2009).

Shen, Y. J., Wong, N. & Lam, E. Y. Robust level-set-based inverse lithography. Opt. Express 19, 5511–5521 (2011).

Shen, Y. J. Level-set based mask synthesis with a vector imaging model. Opt. Express 25, 21775–21785 (2017).

Shen, Y. J., Peng, F. & Zhang, Z. R. Efficient optical proximity correction based on semi-implicit additive operator splitting. Opt. Express 27, 1520–1528 (2019).

Shen, Y. J., Zhou, Y. Z. & Zhang, Z. R. Fast implicit active contour model for inverse lithography. Opt. Express 29, 10036–10047 (2021).

Yu, D., Liu, Y. & Hawkinson, C. The application of a new stochastic search algorithm “Adam” in inverse lithography technology (ILT) in critical recording head fabrication process. Proc. SPIE 11613, Optical Microlithography XXXIV (SPIE, 2021).

Zheng, X. Q. et al. Study of inverse lithography approaches based on deep learning. J. Microelectron. Manuf. 3, 20030301 (2020).

Wang, S. B. et al. Machine learning assisted SRAF placement for full chip. Proc. SPIE 10451, Photomask Technology 2017 (SPIE, Monterey, CA, USA, 2017).

Abbe, E. Beiträge zur Theorie des Mikroskops und der mikroskopischen Wahrnehmung. Arch. f.ür. mikroskopische Anat. 9, 413–468 (1873).

Cecil, T. et al. Advances in inverse lithography. ACS Photonics 10, 910–918 (2023).

Shao, Y. et al. Wavelength-multiplexed multi-mode EUV reflection ptychography based on automatic differentiation. Light Sci. Appl. 13, 196 (2024).

Hinton, G. E. & Salakhutdinov, R. R. Reducing the dimensionality of data with neural networks. Science 313, 504–507 (2006).

Goodfellow, I., Bengio, Y. & Courville, A. Deep Learning (Cambridge, MIT Press, 2016).

Lin, Y. B. et al. Data efficient lithography modeling with residual neural networks and transfer learning. Proc. 2018 International Symposium on Physical Design 82–89 (ACM, Monterey CA, USA, 2018).

Watanabe, Y. et al. Accurate lithography simulation model based on convolutional neural networks. Proceedings of SPIE 10454, Photomask Japan 2017: XXIV Symposium on Photomask and Next-Generation Lithography Mask Technology (SPIE, Yokohama, Japan, 2017).

Hooker, K. et al. Using machine learning etch models in OPC and ILT correction. Proc. SPIE 11614, Design-Process-Technology Co-Optimization XV (SPIE, 2021).

Matsunawa, T., Yu, B. & Pan, D. Z. Optical proximity correction with hierarchical bayes model. Proceedings of SPIE 9426, Optical Microlithography XXVIII (SPIE, San Jose, CA, USA, 2015).

Choi, S., Shim, S. & Shin, Y. Machine learning (ML)-guided OPC using basis functions of polar Fourier transform. Proc. SPIE 9780, Optical Microlithography XXIX (pp. 97800H. SPIE, San Jose, CA, USA, 2016).

Yang, H. Y. et al. Layout hotspot detection with feature tensor generation and deep biased learning. Proc. 54th Annual Design Automation Conference 2017 62 (IEEE, Austin, TX, USA, 2017).

Zhang, H., Yu, B. & Young, E. F. Y. Enabling online learning in lithography hotspot detection with information-theoretic feature optimization. Proc. 2016 IEEE/ACM International Conference on Computer-Aided Design (ICCAD). 1–8 (IEEE, Austin, TX, USA, 2016).

Matsunawa, T. et al. A new lithography hotspot detection framework based on AdaBoost classifier and simplified feature extraction. Proc. SPIE 9427, Design-Process-Technology Co-optimization for Manufacturability IX (SPIE, San Jose, CA, USA, 2015).

Xu, X. Q. et al. A machine learning based framework for sub-resolution assist feature generation. Proceedings of 2016 on International Symposium on Physical Design 161–168 (ACM, Santa Rosa, CA, USA, 2016).

Wang, S. B. et al. Efficient full-chip SRAF placement using machine learning for best accuracy and improved consistency. Proc. SPIE 10587, Optical Microlithography XXXI (SPIE, San Jose, CA, USA, 2018).

Ma, X. et al. Pixelated source and mask optimization for immersion lithography. J. Opt. Soc. Am. A 30, 112–123 (2013).

Ma, X. et al. A fast and manufacture-friendly optical proximity correction based on machine learning. Microelectron. Eng. 168, 15–26 (2017).

LeCun, Y., Bengio, Y. & Hinton, G. Deep learning. Nature 521, 436–444 (2015).

Yasuda, J. et al. Recent progress and future of electron multi-beam mask writer. Jpn. J. Appl. Phys. 62, SG0803 (2023).

Chandramouli, M. et al. Development and deployment of advanced multi-beam mask writer. Proc. SPIE 11324, Novel Patterning Technologies for Semiconductors, MEMS/NEMS and MOEMS 2020 (SPIE, San Jose, CA, USA, 2020).

Kim, B. G. et al. Trade-off between inverse lithography mask complexity and lithographic performance. Proc. SPIE 7379, Photomask and Next-Generation Lithography Mask Technology XVI (SPIE, Yokohama, Japan, 2009).

Pearman, R. et al. How curvilinear mask patterning will enhance the EUV process window: a study using rigorous wafer+mask dual simulation. Proc. SPIE 11178, Photomask Japan 2019: XXVI Symposium on Photomask and Next-Generation Lithography Mask Technology (SPIE, Yokohama, Japan, 2019).

Xiao, G. M. et al. E-beam writing time improvement for inverse lithography technology mask for full-chip. Proc. SPIE 7748, Photomask and Next-Generation Lithography Mask Technology XVII (SPIE, Yokohama, Japan, 2010).

Xiao, G. M. et al. Affordable and process window increasing full chip ILT masks. Proc. SPIE 7823, Photomask Technology 2010 (SPIE, Monterey, CA, USA, 2010).

Pang, L. et al. Enabling faster VSB writing of 193i curvilinear ILT masks that improve wafer process windows for advanced memory applications. Proc. SPIE 11518, Photomask Technology 2020 (SPIE, 2020).

Spence, C. et al. Manufacturing challenges for curvilinear masks. Proc. SPIE 10451, Photomask Technology (SPIE, Monterey, CA, USA, 2017).