In simple terms, almost every modern car uses disk brakes: a rotor connected to a hub with a caliper containing brake pads attached to the control arm at each wheel. When the driver presses the brake pedal, hydraulic fluid is pushed down the brake lines into the caliper, expanding the pistons and pushing the brake pads against the rotor. This slows down the rotation of the rotor attached to the hub, thereby slowing down the wheel.

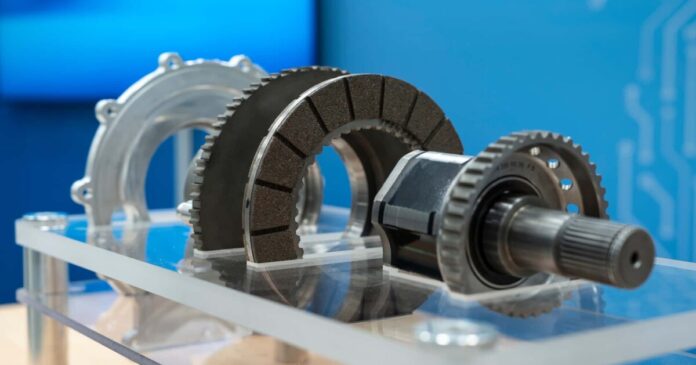

There are other brake systems like drum brakes, air brakes, band brakes, and even compression brake systems that have existed since the early days of the automotive industry. The fundamental concept remains the same – utilizing friction to slow down the vehicle. Mercedes-Benz has introduced a new concept known as “in-drive brakes” for electric vehicles. These brakes are integrated into the drivetrain and work like a transmission brake, resembling clutch plates but with a unique design.

Mercedes-Benz

Instead of calipers, the in-drive brake system features a circular brake pad connected directly to the output shaft of the electric motor, pressed against a stationary water-cooled ring in an enclosed system. Mercedes claims that this system should not need servicing throughout the vehicle’s lifespan, potentially saving owners significant costs on brake repairs and replacements. Even the brake dust is collected within a compartment that does not require emptying.

Brake dust can contribute to pollution, especially in urban areas with heavy stop-and-go traffic. Electric vehicle motors serve as a brake when the accelerator is released, regenerating electricity back into the batteries and slowing the vehicle down. However, a separate brake system is still necessary. The in-drive brake is currently under testing, with Mercedes confident that brake fade will not be an issue due to the water-cooled system.

Mercedes-Benz

The main advantage of in-drive brakes is the elimination of rusty rotors on luxury vehicles like the Mercedes-Maybach EQS 680 SUV, saving owners time and money on repairs. This brake system also reduces the environmental impact by consolidating components and reducing materials needed. With Euro 7 emission standards approaching in 2026, the dust-sealing design of these brakes puts them ahead of the curve.

While Mercedes is revolutionizing traditional brake systems for electric cars, other companies like REE are exploring innovative architectures for electric vehicles. REE’s approach involves placing all components “under the hood” in the wheel wells, creating a modular platform that allows various vehicle types to be built on top. Whether in-drive brakes become standard or remain a premium upgrade for wealthy EV buyers remains to be seen.

Source: Inside EVs