5G is quickly becoming a standard in developed countries, offering benefits like reduced latency for driverless vehicles and connecting millions of devices per square mile for the Internet of Things. The University of Sheffield in the UK is working on a project to bring these advances to disadvantaged and remote areas.

Main 5G Infrastructures and Bands

Deploying 5G networks requires significant investments in radio spectrum and hardware like antennas. There are two types of architecture: Non-Stand Alone (NSA) and Stand Alone (SA). NSA architecture utilizes existing 4G infrastructure with limited functionalities, while SA architecture offers the full potential of 5G with lower latency and higher speeds.

5G antennas are also classified by the bands they operate in, such as Sub-6 and mmWave. Sub-6 operates below 6 GHz and is used in urban environments, while mmWave operates at higher frequencies for faster speeds but requires more repeaters for coverage.

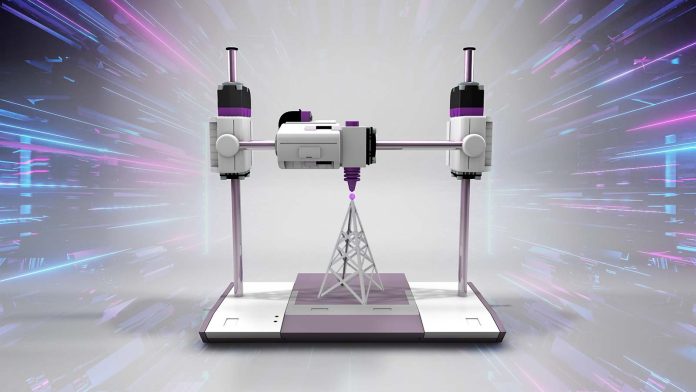

3D Printing of 5G and 6G Antennas

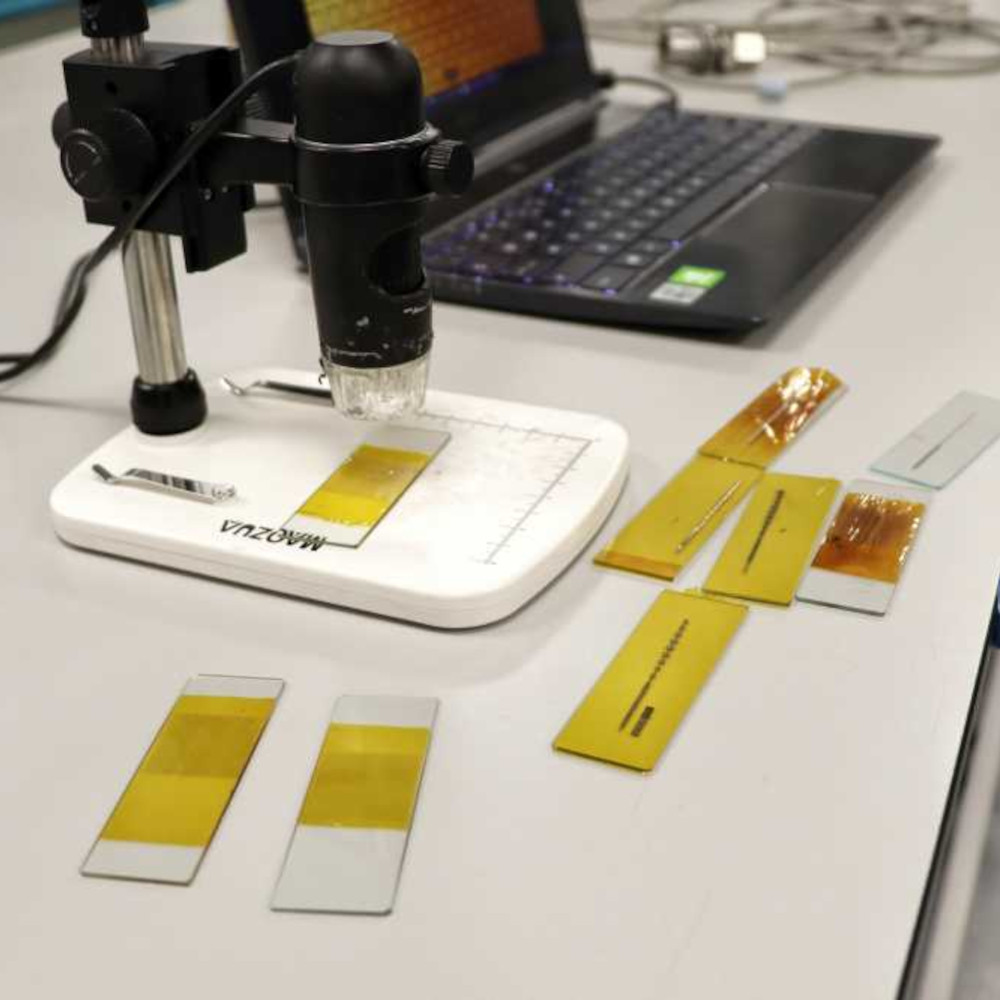

3D-printed mmWave antennas are crucial for maximizing 5G technology. The University of Sheffield has developed 3D-printed 5G and 6G antennas using silver nanoparticles, drastically reducing costs and production times compared to traditional antennas.

This new design allows for the production of large-scale, low-cost antennas to reach remote areas efficiently. This technology focuses on miniaturization, cost-effectiveness, and ease of installation, making it valuable for developing countries.

Technology advancements, like 3D-printed antennas, bring opportunities for underprivileged areas. Projects like solar desalination plants and initiatives by organizations like the Acciona Foundation in providing clean energy to remote regions showcase the impact of technological innovations.

A New Age of Additive Manufacturing Electronics

3D printing can be used to produce semiconductors, sensors, transistors, and other electronic components, opening new possibilities for wearable technology. Additive Manufacturing Electronics (AME) is a growing field with potential to reach $40 billion by 2030.

Projects like the thermoelectric device created at the University of Washington, which converts body heat into electricity, demonstrate the capabilities of 3D printing in electronics manufacturing. These innovations could revolutionize the electronics industry in the coming years.

Source: