The advancement of architecture and construction showcases the progress of humanity throughout history, highlighting our aesthetic visions and technological achievements. Today’s architectural scene is filled with skyscrapers, airports, and large stadiums, while the construction industry is abuzz with terms like 3D printing, robotics, artificial intelligence, augmented reality, and exoskeletons. A new robotic invention in this field aims to significantly reduce construction time by efficiently placing hundreds of blocks per hour.

Improving efficiency with construction robotics

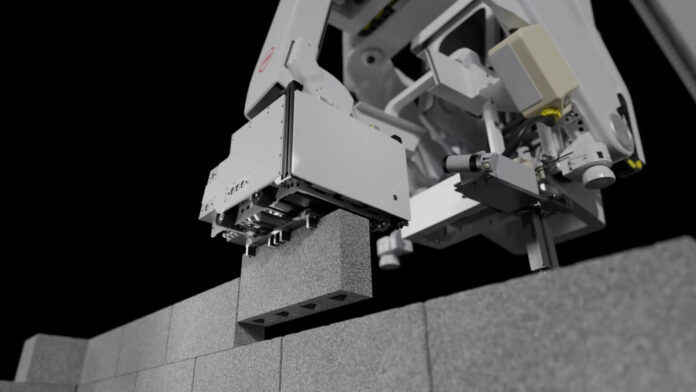

The Hadrian X, developed by an Australian company, represents a breakthrough in masonry technology. Its goal is to automate and optimize the construction of brick walls, offering a faster and more efficient method compared to traditional techniques. The robot features a thirty-two-meter-long telescopic arm mounted on a truck, which is designed to accurately position each block. It also comes equipped with an advanced vision system to determine the best brick arrangement, allowing for precise placement.

The ability of this robot to automate tasks enables continuous operation without interruptions, significantly speeding up construction work in any weather conditions. It is capable of constructing walls rapidly, initially reaching speeds of 300 blocks per hour, with the potential to achieve speeds of up to 500 blocks per hour. This innovation has the potential to reduce the need for labor and minimize associated risks in the construction sector.

Instead of using cement, the system utilizes a new adhesive to secure blocks weighing up to forty-five kilograms and measuring 600 x 400 x 300 mm. As a result, it can erect up to seventy square meters of wall per hour and construct up to three stories high without the need for ladders or scaffolding, also reducing material wastage.

Unlike other technologies that are still in development, this robot has moved beyond the prototype stage, with demonstrations in real-world scenarios since its inception in 2015 for commercial purposes by 2023. The company is planning to release second and third-generation models soon.

How does the masonry robot operate?

This innovation begins with digital CAD drawings outlining the structure of the building. An operator then uses a tablet to direct the robotic arm to the starting point of the construction.

While robotics in construction is advancing, human supervision is still necessary. In addition to the operator guiding and monitoring the robot for safety, extra personnel are needed to load blocks onto the truck. Other robotic systems handle the organization of these blocks and, if required, cutting them to size. Before placement, the blocks are coated with the special adhesive, which sets within forty-five minutes.

However, tasks such as wiring installation, roofing, plumbing, and ventilation systems still rely on human involvement. Therefore, while these robots are valuable assistants, their full potential in large-scale and complex constructions is yet to be fully realized.

Looking ahead, the integration of artificial intelligence and machine learning is expected to further enhance the capabilities of these robots, making construction processes more efficient and sustainable.

If you are interested in learning more about the application of robotics in construction and the use of new materials, we recommend reading an article on the use of 3D printing to manufacture unique furniture pieces.

Source:

Photos: