Researchers at the Indian Institute of Science (IISc) and the Qatar Science and Technology Research Center (QSRTC) have developed a new automated method to assess corrosion in industrial equipment using advanced machine learning and image analysis.

Published in npj Materials Degradation, the study describes a novel machine learning algorithm that can analyze microscope images of corroded metal surfaces to estimate corrosion severity, without requiring human input.

“Corrosion poses significant economic and safety challenges in industries like power generation and oil/gas,” says Phaneendra K Yalavarthy, Professor at the Department of Computational and Data Sciences (CDS), IISc, and senior author of the study.

“[It] silently compromises the integrity of these systems, putting lives and livelihoods at risk and burdening society with escalating maintenance costs,” adds co-author Ashwin RajKumar, former postdoctoral researcher at CDS.

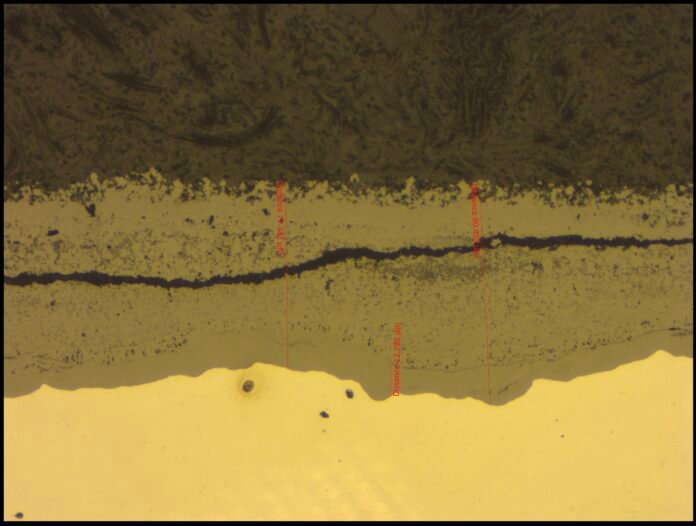

The AI-based technique focuses on two critical indicators of corrosion: the thickness of corrosive deposits on the surface of metals and the porosity (number of tiny holes) within those deposits.

When microscopy images of metal surfaces are fed to the algorithm, it can quantify these two characteristics and infer key features that indicate how much corrosion has happened. These features include the concentration of corrosive chemicals and the acidity of the environment beneath the deposits.

“As the rust-like deposits get thicker, there’s more chloride present, and the surface becomes more acidic,” explains Yalavarthy.

“We identified specific pH levels that indicate when corrosion is worsening. For example, when the pH drops below 2.8–3, it means that the corrosion has reached a very severe stage.”

“It was striking to see such a strong and consistent correlation between local pH and corrosion stage, especially the threshold at pH ~2.8–3 that delineates the transition from Stage 3 to Stage 4,” says RajKumar.

“This suggests that surface morphology and local chemistry are more tightly coupled than previously appreciated, offering a valuable predictive marker for escalation in corrosion severity.”

The researchers tested their method in checking the under-deposit corrosion (UDC) of steam generator tubes—a particularly challenging and prevalent form of corrosion in industrial boilers and other high-temperature environments.

“[The algorithm] is quite accurate, getting it right about 73% of the time,” says Yalavarthy. “[It] is faster and more consistent than having people manually examine the optical microscopy images to determine the severity of corrosion.”

What also sets this method apart is its unsupervised learning approach—it does not rely on predefined class labels or manually annotated datasets, which are often scarce or inconsistent in corrosion studies.

Instead, it employs k-means clustering, a machine-learning technique that segments microscopy images into distinct regions (such as deposits and pores) without prior assumptions about their appearance. This is particularly useful when corrosion product structures are complex and vary significantly.

While the approach may be adapted to a variety of corrosion product morphologies, it would need to be tailored to each specific case, since morphological features differ across corrosion mechanisms, the researchers caution.

“The next critical step is to validate the algorithm on much larger and more diverse datasets, capturing the full spectrum of deposit morphologies and operating conditions encountered in industrial practice,” says RajKumar.

Such a technique is promising for industrial maintenance and operations, as it can enable quantitative, data-driven corrosion assessment across facilities and sectors. Integrating it with digital monitoring systems can further contribute towards industrial digitalization, offering meaningful benefits in safety, operational efficiency, and materials science research.

“Drawing from our background in biomedical image analysis—where optical microscopy and automated detection already save lives—we were inspired to bring similar intelligence and rigor to corrosion science,” says Yalavarthy.

More information:

Ashwin RajKumar et al, Unsupervised machine learning for automated corrosion staging using optical microscopy images, npj Materials Degradation (2025). DOI: 10.1038/s41529-025-00635-1

Provided by

Indian Institute of Science

Citation:

Advanced corrosion assessment using AI-powered imaging technology (2025, July 23)

retrieved 23 July 2025

from https://phys.org/news/2025-07-advanced-corrosion-ai-powered-imaging.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.