Even though autonomous, unmanned ships are currently undergoing trials, they still require human workers to moor them upon arrival at port. However, a new automated suction-based mooring system may change that soon.

Typically, ships are secured to piers using thick ropes called mooring lines or hawsers. These lines are tied to fittings on the vessel’s deck and to cleats or fittings on the pier. Teams of workers are needed to handle and secure these lines.

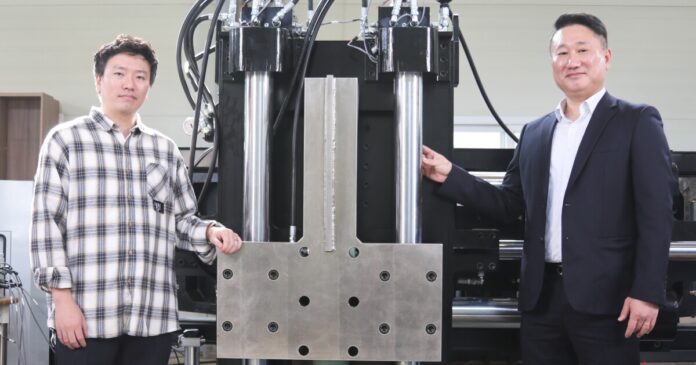

Developed by Dr. Yongjin Kim and his team at The Korea Institute of Machinery and Materials (KIMM), this new system is designed to eliminate the need for human teams and mooring lines. It is intended for use on fully or partially automated piers.

The mooring process begins with a tugboat guiding the ship into the harbor, where it rests against a row of fenders along the pier’s side. A steel pad extends from a mooring module on the pier, containing rubber suction cups that adhere to the ship’s hull. A hydraulic system creates a vacuum inside these cups to secure them to the vessel.

Both the adjustable-angle pad and the hydraulic system can move vertically and horizontally relative to the pier to adjust to the hull angle of each ship and accommodate changes in tide. The hydraulic system renews the vacuum every hour to maintain a solid seal. When it’s time for the ship to depart, the seal is released, and the pad is retracted.

KIMM

Real-world testing of the system is planned for the next year, followed by the commercialization of this technology. Dr. Kim believes that “This automated mooring system represents a key advancement in the safe docking of autonomous vessels and will play a pivotal role in the development of smart port infrastructure. We expect this solution to set a new standard in operational safety and efficiency across the marine industry.”

Source: KIMM