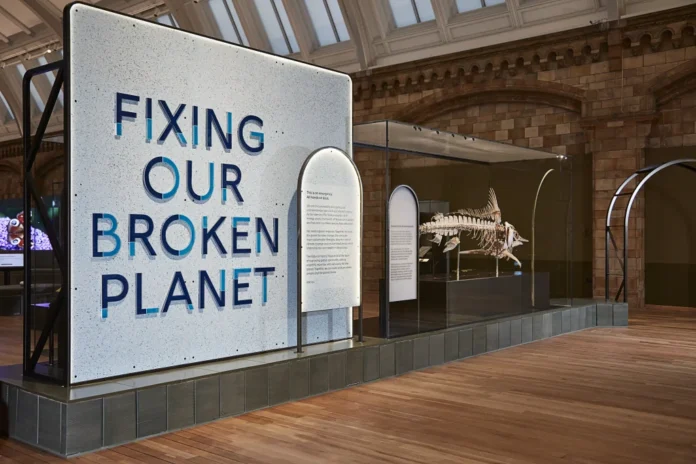

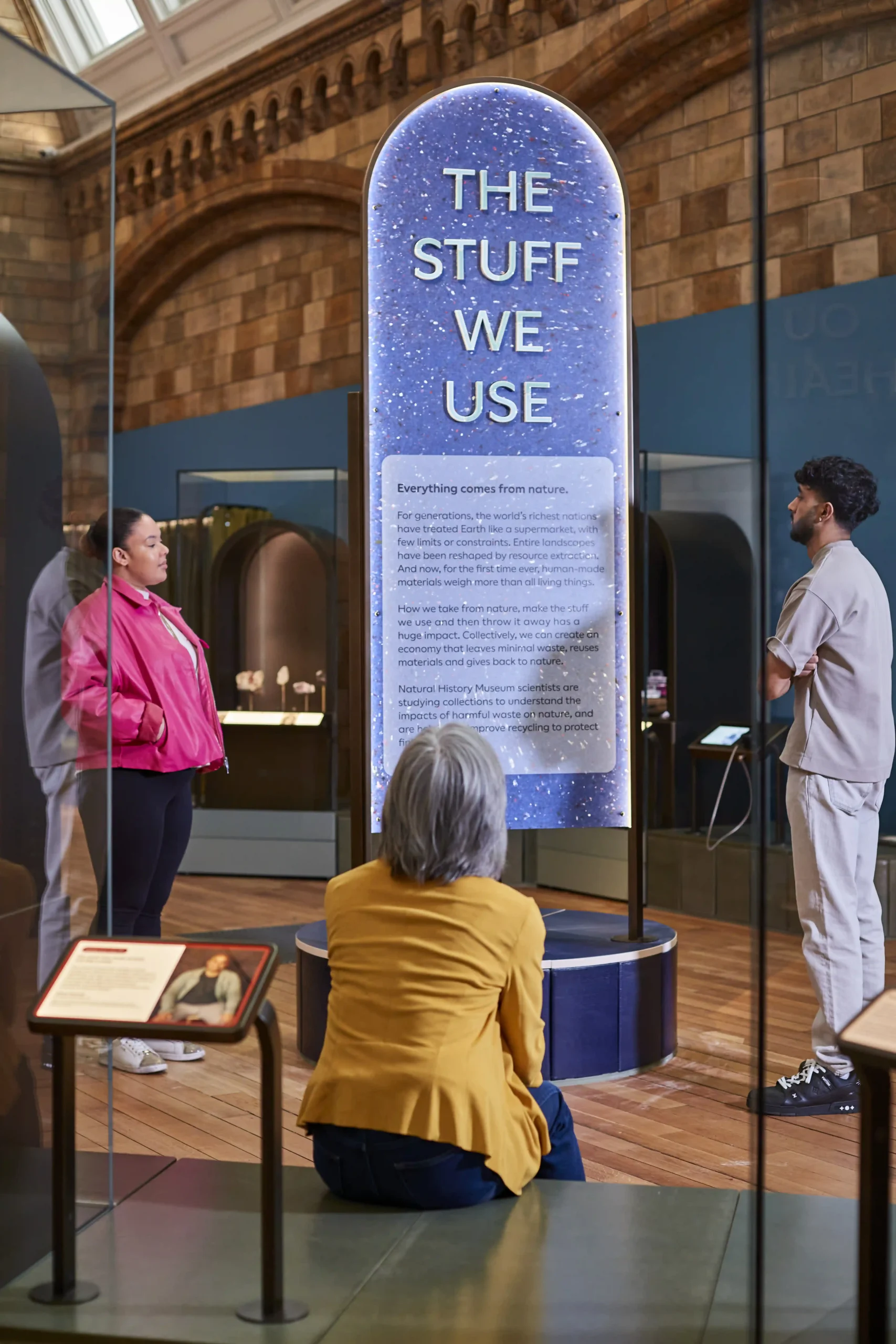

Fixing Our Broken Planet is a major gallery at the Natural History Museum (NHM) in London, conceived as the first of six new spaces marking the institution’s 150th anniversary. The gallery includes over 200 objects from the natural world, research findings from over 30 Museum scientists, and the chance for audiences to have their say on the planetary emergency.

The design of this decade-long temporary exhibition was led by the NHM’s in-house team of architects, with particular consideration to the environmental impact of the intervention while maintaining both design integrity and long-term durability. One key strategy is the use of 3D printing ceramics for display cases, furniture, live benches, and signage supports.

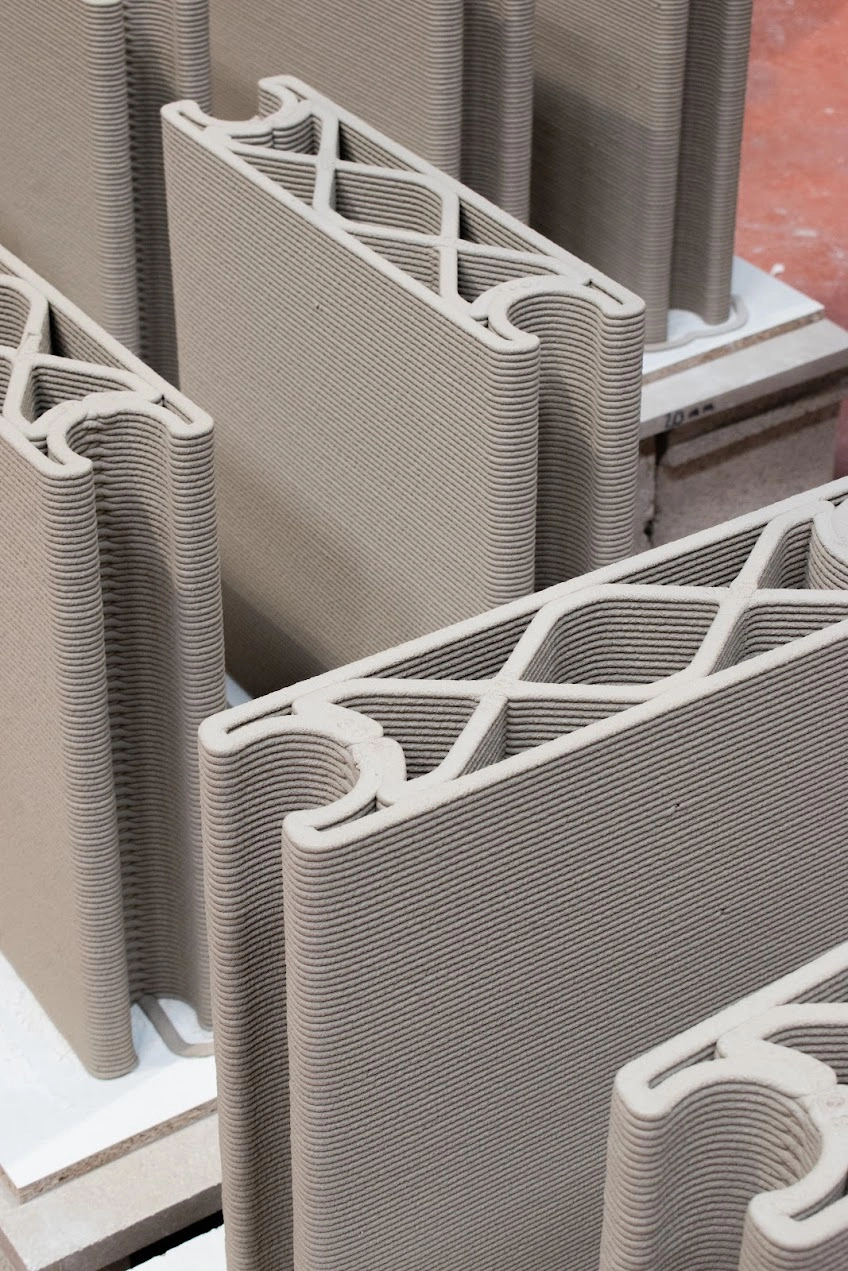

LAMÁQUINA collaborated with the engineering of the design and the manufacturing to produce all the pieces with 40% recycled clay coming from the ceramic industry. The entire process was precisely planned to eliminate material waste. Two different clay production techniques were employed: 3D printing for the bases and 2D tiling for top horizontal capping elements. The bases feature a specific contour that allows for dry assembly using biopolymer joints, while the tiles serve to bind the structure. This approach also enables easy disassembly for the future, supporting the project’s circular approach.

The design was systematised into ten modules, used in various combinations to suit the exhibition’s content. These modules were standardized into pieces to streamline both production and installation. A total of 1,686 individual components were manufactured in less than three months. Robotic precision ensured each one was shaped as needed, integrating all technical requirements, including perforations for cables and signage.

To stabilise each element and optimise structural integrity, special attention was given to the internal geometry. The infill was engineered not only to reinforce and stabilise each printed piece but also to minimise weight while maintaining strength.

Due to the restrictions of working within a heritage site, the intervention, both in its final result and during installation, could not make any contact with the walls or impose point loads exceeding 400 kg. These limitations not only shaped the design but also the logistics strategy, with an installation completed in only ten days.

With Fixing Our Broken Planet, the Museum exemplifies how innovation and sustainability can coexist within a heritage context, setting a benchmark for future exhibitions. As Doug Gurr, the Museum Director, remarked at the exhibition’s opening: “This is not only talking the talk on sustainability, it is walking the walk.”

Project Details

Project name: Fixing Our Broken Planet gallery at the Natural History Museum

Design: Natural History Museum

3D Printing: LAMÁQUINA

Galzing and firing: Ceràmica Cumella

Technology: WASP

Location: London, United Kingdom