A groundbreaking proof-of-concept project has successfully created nanoscale diodes and transistors using a rapid and cost-effective new production method where liquid metal is guided to self-assemble into precise 3D structures.

In an upcoming publication in the journal Materials Horizons, a team from North Carolina State University detailed and demonstrated the innovative technique using a blend of indium, bismuth, and tin known as Field’s metal.

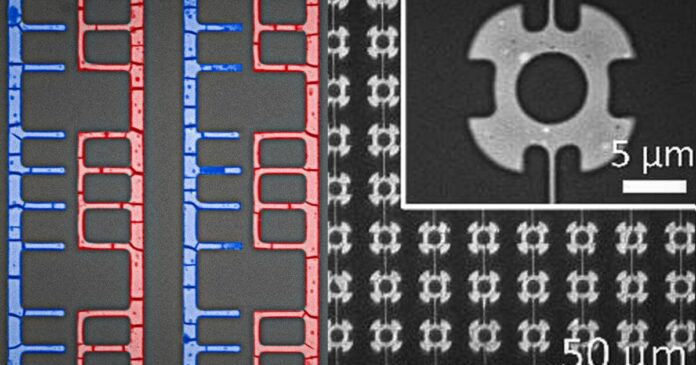

The process involves placing liquid metal next to a mold, which can be customized in size and shape. When exposed to oxygen, a thin oxide layer forms on the metal’s surface. Subsequently, a solution containing negatively charged ligand molecules is poured over it, which attracts individual metal atoms as positively charged ions and binds with them.

These metal ions held in the ligands act like magnetic building blocks, attracted to each other. As the ligand solution flows through channels in the mold through capillary action, it pulls these building blocks along, causing them to align into orderly structures like wires and adhere to each other.

Julia Chang/NC State University

“Without the mold, these structures can form somewhat chaotic patterns,” explains Martin Thuo, the corresponding author and professor of materials science and engineering at North Carolina State University. “But because the solution is constrained by the mold, the structures form in predictable, symmetrical arrays.”