Eduardo Chillida, the Basque artist, installed one of his best-known series of sculptures on the breakwater of Donostia and called it “The Comb of the Wind.” There is a resemblance to the wind turbines that are now appearing in coastal waters worldwide. By 2021, the energy capacity of these “wind combs” is set to nearly double, reaching 48.2 GW. Additionally, floating offshore wind has become a significant part of total installed wind farm capacity globally.

This article covers the following topics:

What is floating offshore wind, and how does it work?

The conventional method for offshore wind farms involves placing structures in shallow coastal waters where offshore winds are more stable and intense compared to onshore areas hindered by obstacles such as mountains and forests.

Installing these wind turbines securely on the seabed to withstand waves poses a challenge, limiting options to shallow waters near the coast. Floating platforms, known as Floating Offshore Wind Platforms (FOWP), overcome these limitations by using floating structures attached to platforms with cables providing mobility during strong waves.

Advantages of floating offshore wind turbines

Floating offshore wind energy offers various benefits including the ability to be installed in deep waters, easy relocation, reduced environmental impact on the seabed, lower installation costs, harnessing stronger winds, and less visual impact by being situated farther from the coast.

Types of floating offshore wind

While wind turbines on floating platforms share similarities, the main variations lie in the type of floating platforms used. Options include spar buoy, barge or pontoon model, semi-submersible base, and TLP model (Tension Leg Platform).

Wind pyramids: an innovative approach

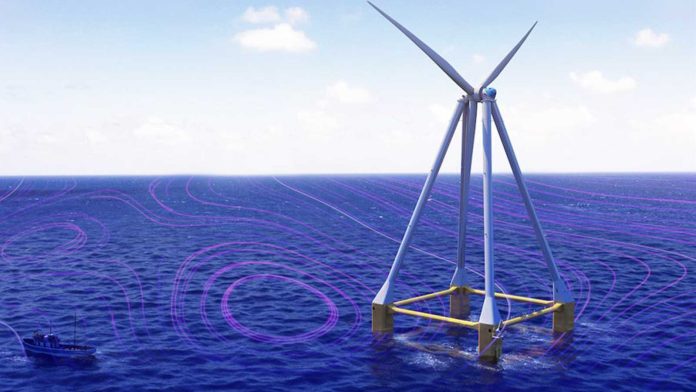

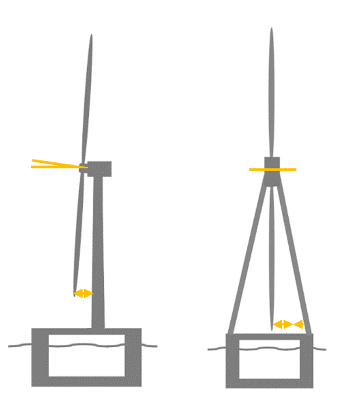

A unique approach is the “pyramidal” turbines proposed by the French company Eolink, designed specifically for floating offshore wind to leverage the environment’s characteristics. By eliminating the nacelle and using a pyramidal structure with four masts, these turbines offer improved energy efficiency and durability.

The pyramid design reduces wear and tear on the structure, allowing for longer and more flexible blades, resulting in higher energy efficiency. New wind turbines utilizing this design could produce 20 MW per unit with 20-25% greater efficiency than current solutions.

While still in the prototype phase, plans are underway to install a 5 MW demonstration wind turbine in the near future.

Sources